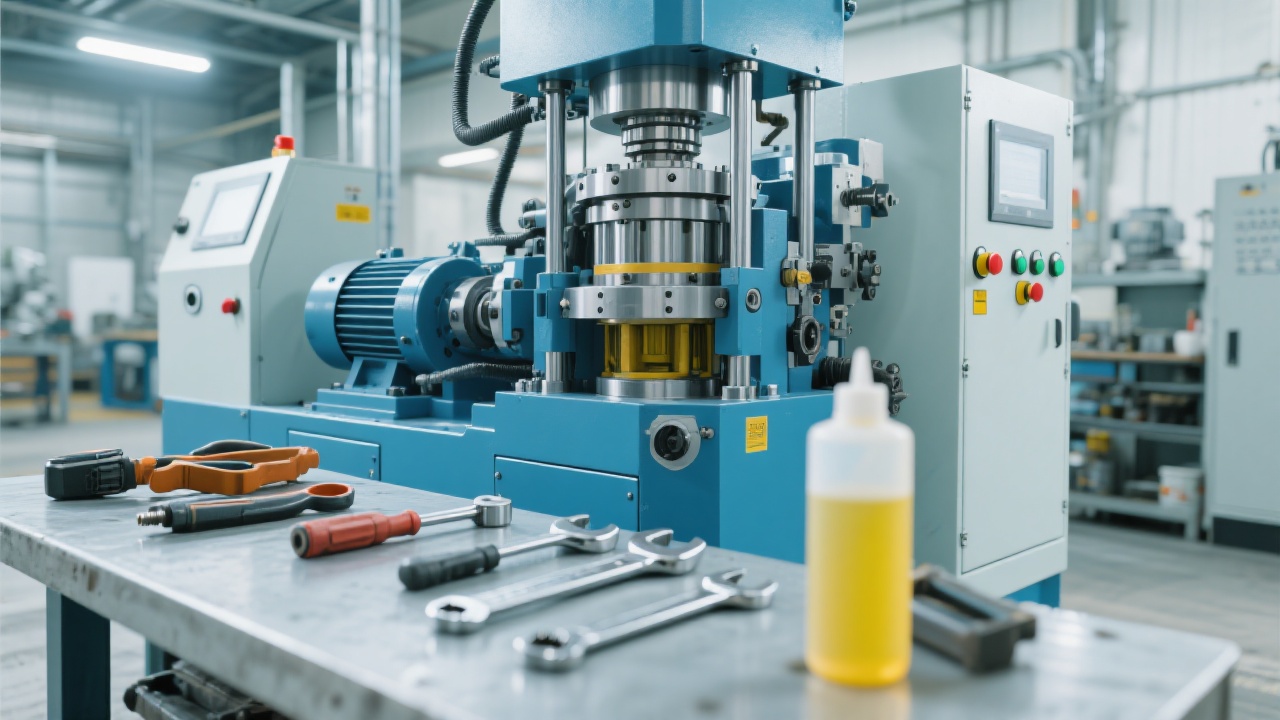

The sunflower seed oil extraction machine tailored for households and small farms stands at the forefront of efficient, sustainable oil production. Designed with the philosophy of “making every sunflower seed count,” this compact yet robust equipment merges advanced technology with operational simplicity. In industries where quality and cost-efficiency are paramount, upgrading to such machinery is no longer optional—it’s essential: save power, save worries, it’s time to revolutionize your oil pressing method!

The primary users of this sunflower seed oil extractor are intimate-scale producers who value simplicity without sacrificing output quality. These include home users pursuing healthier cooking oils and small to mid-sized farms seeking local processing capabilities. The equipment's compact footprint and user-friendly design mean it fits seamlessly into diverse environments—from rural kitchens in Asia to agro-processing hubs in South America or Africa.

The extractor implements a streamlined workflow, integrating seed cleaning, pressing, and filtration into one continuous operation that enhances productivity while maintaining product purity. The process begins with thorough seed cleaning eliminating impurities to protect the pressing components and improve oil quality. This is followed by high-efficiency cold pressing, maximizing oil yield without harmful heat degradation. Finally, built-in filtration systems ensure clarity and safety of the edible oil.

| Process Stage | Description | Benefit |

|---|---|---|

| Seed Cleaning | Removal of dust, stones, and debris | Protects equipment, improves oil taste |

| Cold Pressing | Mechanical extraction without added heat | Preserves nutrients, achieves ≥42% oil yield |

| Filtration | Removing residual solids and impurities | Ensures clarity, extends shelf life |

Crafted from high-strength, food-grade stainless steel, the device meets ISO9001 quality standards. This certification underscores strict control in design, manufacturing, and safety. Stainless steel ensures durability against corrosion and facilitates effortless cleaning—a priority for both household users and commercial producers aiming to maintain hygiene and food safety.

Remarkably, the sunflower seed oil extractor achieves an oil extraction rate of at least 42%, significantly outpacing traditional mechanical presses by roughly 10-15%. Meanwhile, its innovative motor and pressure regulation system cuts power use by nearly 30%, aligning with green production goals and reducing operational costs.

| Performance Indicator | Traditional Press | Our Extractor |

|---|---|---|

| Oil Yield (%) | 30 - 35 | ≥42 |

| Energy Consumption (kWh/100kg seeds) | 22 - 25 | 15 - 17 |

| Processing Capacity (kg/hr) | 50 - 70 | 60 - 80 |

Available either as standalone units or integrated into customizable processing lines, the extractor is designed for versatility. Modules can be added or removed depending on throughput requirements, allowing seamless scaling from family use to small industrial setups. Its proven adaptability fits diverse agricultural and regulatory frameworks across Asia, Africa, and South America, making it a trusted global choice.

It features a modular build allowing components like pressing screws, filters, and seed cleaners to be swiftly detached for inspection or replacement. Surfaces are engineered for effortless cleaning, minimizing downtime and ensuring hygiene compliance. Daily upkeep involves basic lubrication, debris removal, and component checks, enabling operators—even novices—to maintain peak functionality.

Confidence in long-term performance is reinforced by a comprehensive 12-month warranty covering parts and workmanship. Beyond warranty, dedicated global technical support networks provide timely troubleshooting and spare parts supply. This peace of mind empowers customers to focus entirely on efficient oil production.

The sunflower seed oil extractor consistently delivers an oil yield of ≥42%, outperforming many traditional models.

Yes, it reduces energy consumption by about 30%, thanks to innovative motor designs and operational optimization.

The modular design allows easy detachment of key parts for cleaning and maintenance—tasks can be completed swiftly without specialized tools.