In the competitive landscape of the global edible oil market, the demand for high-quality sunflower oil is on the rise. For overseas processing enterprises, having a reliable and efficient small-scale sunflower oil press is crucial to meet this demand and enhance their market competitiveness. Penguin Group is proud to introduce its next-generation high-efficiency small-scale sunflower oil press, which is designed to provide outstanding performance and comprehensive technical support.

The operation of Penguin Group's sunflower oil press is a well-structured process that starts with seed pre-treatment. Before the seeds are fed into the press, they need to be cleaned and dried to ensure optimal oil extraction. The moisture content of the seeds should be around 8 - 10% for the best results. After pre-treatment, the seeds are ready to be loaded into the hopper of the press.

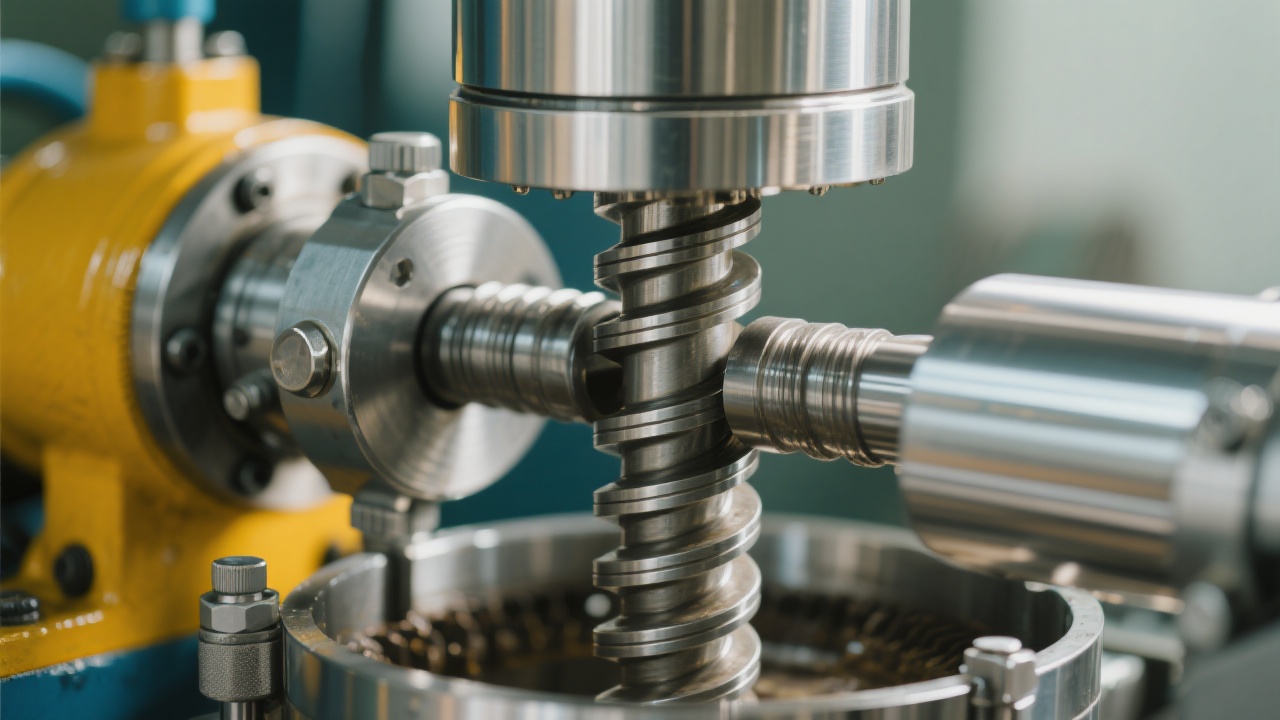

Once the seeds are in the hopper, the press is started. The machine uses advanced screw pressing technology to gradually increase the pressure on the seeds, squeezing out the oil. The entire pressing process is carefully controlled to ensure high oil extraction efficiency. On average, the oil extraction rate can reach up to 40 - 45%, which is significantly higher than many other similar products in the market.

After the pressing, the crude oil needs to be filtered to remove any impurities. Penguin Group's oil press is equipped with a high-quality filtration system that can effectively remove solid particles and other contaminants, resulting in clear and pure sunflower oil.

Proper maintenance is essential to ensure the long-term performance and reliability of the sunflower oil press. Penguin Group provides detailed maintenance guidelines to help users keep their machines in good condition. Regular maintenance tasks include cleaning the residue from the press chamber, lubricating the moving parts, and checking the condition of the key components.

In case of any problems, Penguin Group offers comprehensive troubleshooting support. The company's technical experts have in-depth knowledge of the product and can quickly diagnose and solve various issues. For example, if the oil output suddenly decreases, it could be due to a blocked filter or a worn-out screw. By following the troubleshooting guide provided by Penguin Group, users can easily identify and fix the problem.

Safety is always a top priority when operating any industrial equipment. Penguin Group's sunflower oil press is designed with multiple safety features to protect the operators. However, it is still important for users to follow the safety guidelines strictly. For example, operators should wear appropriate protective clothing and gloves, and avoid touching the moving parts of the machine during operation.

| Question | Answer |

|---|---|

| What is the daily processing capacity of the small-scale sunflower oil press? | The daily processing capacity can range from 500 kg to 2 tons, depending on the specific model and operating conditions. |

| Can the press be used for other types of oilseeds? | Yes, with some adjustments, the press can also be used to extract oil from other oilseeds such as rapeseed, soybean, and peanut. |

| What kind of technical support does Penguin Group provide? | Penguin Group offers 24/7 technical support, including online guidance, on-site maintenance, and spare parts supply. |

Penguin Group's next-generation high-efficiency small-scale sunflower oil press is a reliable and cost-effective solution for overseas processing enterprises. With its advanced technology, high oil extraction rate, and comprehensive technical support, it can help users improve their production capacity and produce high-quality green and healthy edible oil. Don't miss this opportunity to take your business to the next level!

Ready to enhance your sunflower oil production? Explore Penguin Group's small-scale sunflower oil press now!