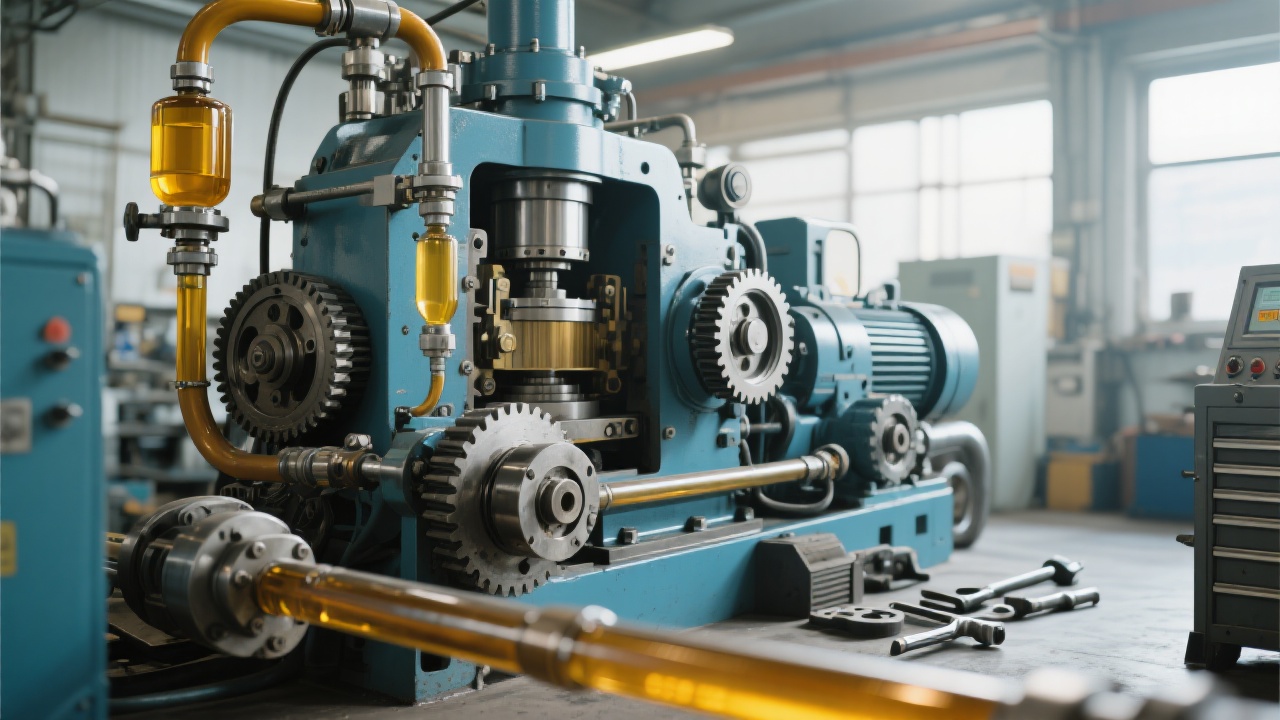

You're not alone if your home oil press isn't delivering the expected output—many users report up to 20–30% lower yields than advertised, especially when using sunflower seeds. The issue rarely lies with the machine itself—it’s usually in how it's maintained or operated.

| Checkpoint | What to Verify | Ideal Range / Tip |

|---|---|---|

| Seed Moisture Content | Use a moisture meter or feel test | 7–10% is optimal for pressing |

| Pre-cleaning Process | Remove dust, stems, and foreign particles | >95% purity increases yield by ~15% |

| Seal Integrity | Inspect gaskets and pressure chamber | Leaks reduce efficiency by 10–25% |

| Maintenance Schedule | Clean die plates monthly; lubricate moving parts weekly | Neglect leads to 30% faster wear and yield drop |

“After following the pre-press cleaning steps, I saw a 22% increase in oil yield within just two batches.” — Maria L., Home Food Processor, Germany

In a side-by-side comparison of two identical models—one regularly maintained and one neglected—the well-maintained unit produced an average of 420g per kg of sunflower seeds, while the other yielded only 290g/kg. That’s a 45% difference over 6 months of use. The key? Consistent sealing checks, proper seed prep, and timely part replacements.

Even small deviations like skipping a weekly wipe-down of the screw press can cause friction buildup, leading to inconsistent pressure and wasted energy. It’s not just about running the machine—it’s about treating it like a precision tool.

If you’re facing low yields or inconsistent results, don’t assume your press is faulty—start with these proven operational habits. They’ll help you maximize every batch, protect your investment, and enjoy consistent, high-quality homemade oil.

Get a free diagnostic checklist + personalized advice from our technical team based on your current setup.

Download Your Free Optimization Guide Now