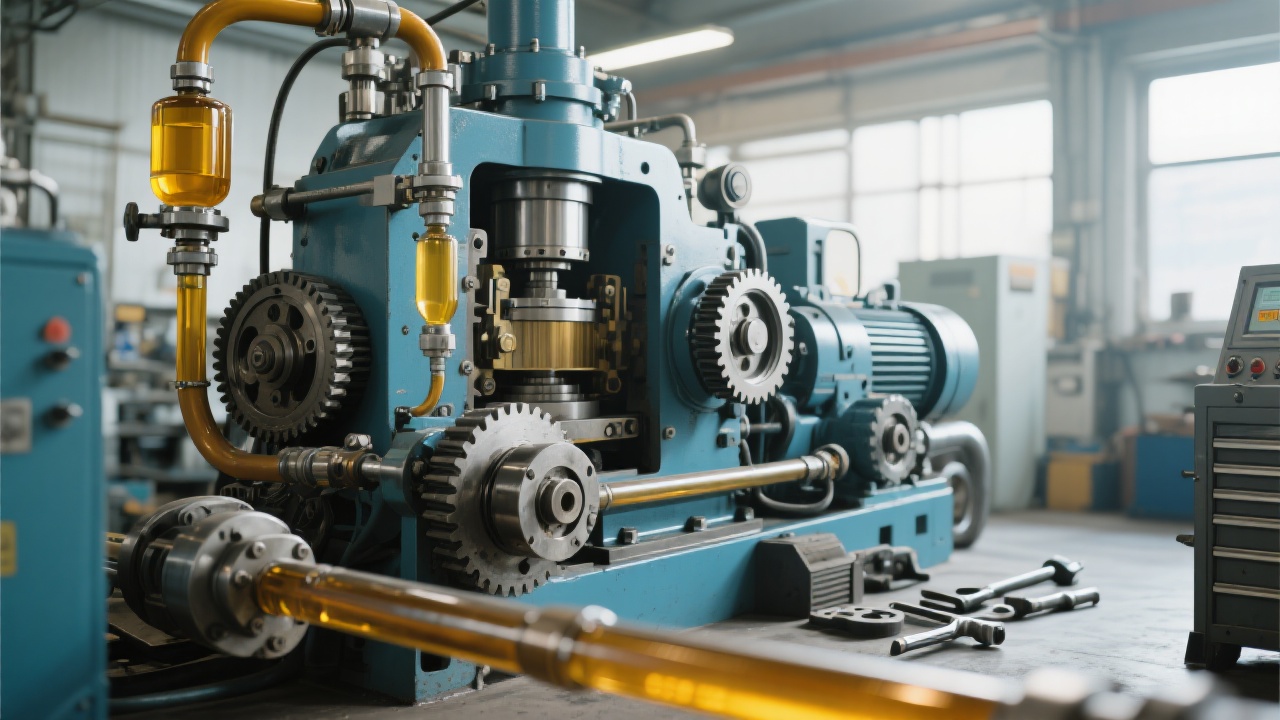

For home users, maximizing the oil yield from a small sunflower oil press is both an economic and practical concern. This article delves into the key techniques and practical tips for enhancing the oil extraction rate, covering raw material pretreatment, pressing temperature control, and pressure adjustment.

Several factors play crucial roles in the mechanical pressing process that can significantly impact the oil yield. These include the pretreatment of raw materials, the relationship between pressing temperature and oil release, and the operation skills and parameter settings of pressure adjustment.

Proper raw material pretreatment is the first step to optimize the oil extraction process. Two main aspects need attention: the drying degree and the crushing particle size of sunflower seeds.

Sunflower seeds should be dried to an appropriate moisture content. Generally, a moisture content of around 8 - 10% is ideal. If the seeds are too wet, the oil will be difficult to separate from the pulp, resulting in lower oil yield. On the other hand, overly dry seeds may cause the oil cells to rupture prematurely, leading to oil loss during the pressing process.

The size of crushed sunflower seeds also affects the oil yield. A suitable particle size allows for better contact between the seeds and the pressing mechanism, facilitating the release of oil. A particle size of about 2 - 3 mm is recommended for optimal results.

The relationship between pressing temperature and oil release is based on the technical principle that higher temperatures can reduce the viscosity of oil and make it easier to flow out. However, excessive temperatures can also cause the oil to oxidize and affect its quality.

For sunflower oil extraction, a pressing temperature of around 100 - 120°C is generally considered optimal. This temperature range can effectively release the oil while maintaining its quality.

Proper pressure adjustment is essential for efficient oil extraction. The pressure should be gradually increased during the pressing process to ensure that the oil is released steadily. A recommended initial pressure of around 5 - 10 MPa can be gradually increased to 20 - 30 MPa as the pressing progresses.

Here is a simple 'Three - Step Guide to Optimize Oil Yield':

There are several common mistakes that home users may make during the oil extraction process. For example, improper raw material pretreatment, incorrect temperature settings, and inappropriate pressure adjustment.

If the seeds are not dried properly, they can be further dried in a low - temperature oven or under the sun. If the temperature is too high, the power supply can be adjusted to lower the temperature. And if the pressure is not adjusted correctly, refer to the user manual for the correct parameter settings.

Our small household oil presses are designed with high - efficiency, stability, and environmental - friendliness in mind. The advanced technology ensures that you can achieve optimal oil yield with ease. Moreover, our professional after - sales service team is always ready to provide you with support and guidance.

If you have any questions or need further information about our products, please feel free to leave a message below. We encourage you to explore our small household oil presses and take your home oil extraction to the next level!