Are you struggling with low oil yield from your household oil press? Don't rush to replace the equipment! This article delves deep into the full - process influencing factors, from raw material moisture content, pre - treatment methods to equipment cleaning and maintenance. It provides a practical troubleshooting checklist and optimization techniques to help you scientifically improve oil production efficiency.

Before we start analyzing the reasons, let's first look at some common phenomena of insufficient oil yield and the misunderstandings you might have. Many users may directly blame the equipment when they see low oil yield, but in fact, the problem could lie elsewhere. For example, you might think the machine is broken just because the oil output is not as expected, while it could be due to improper handling of the raw materials.

The raw material is the first step in the oil - pressing process. Moisture content, freshness, and impurity content all have a significant impact on the oil yield. For instance, when the moisture content of sunflower seeds exceeds 12%, the oil yield can drop by about 30%. Freshness also matters. Old seeds may have lower oil content due to oxidation. And if there are too many impurities in the seeds, they can block the oil - pressing channels, reducing the oil output.

In the pre - treatment stage, operations such as sieving, impurity removal, and seed roasting temperature control are crucial. Sieving can effectively remove large impurities, while proper roasting can break down the cell walls of the seeds, making it easier for the oil to be extracted. The ideal roasting temperature for sunflower seeds is around 120 - 130°C. If the temperature is too high, the oil may be burned; if it's too low, the oil won't be released efficiently.

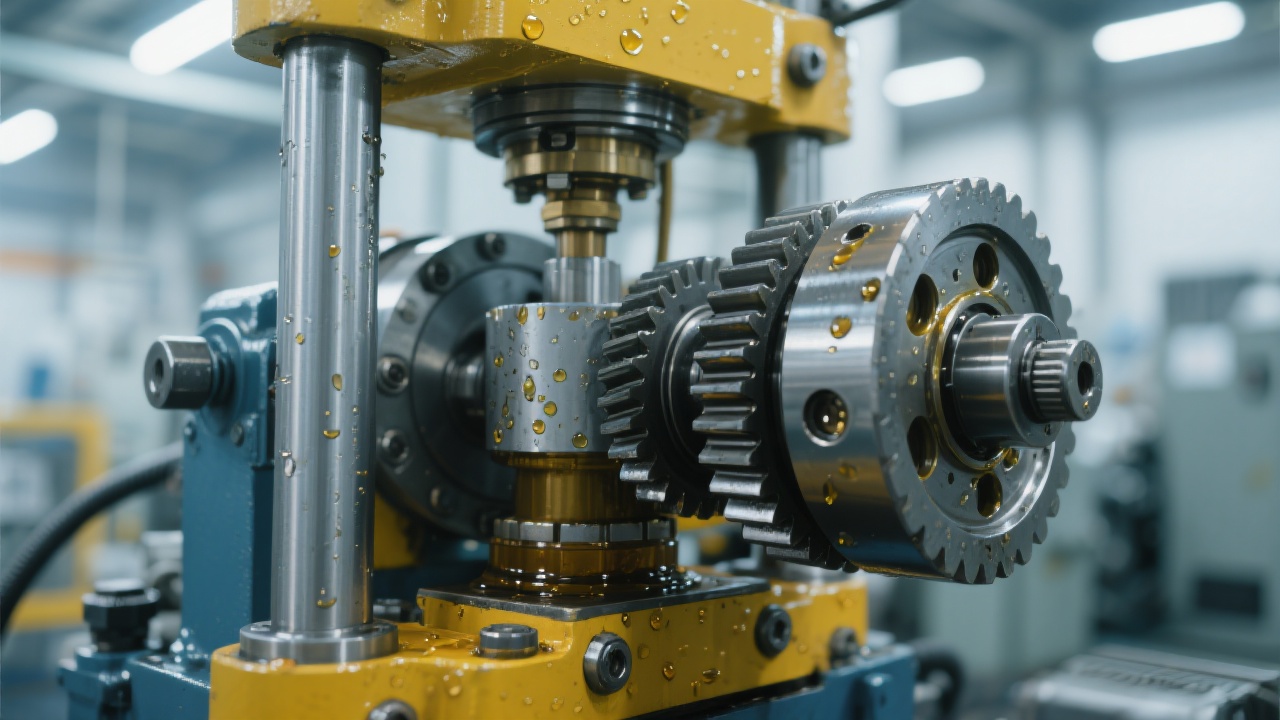

The operation status of the equipment also plays a vital role. You need to check the sealing performance, pressing pressure, cleanliness, and component wear. A poor - sealing machine can cause oil leakage, reducing the oil yield. Insufficient pressing pressure may not be able to squeeze out all the oil. Dirty equipment and worn - out components can also lead to low oil output. For example, if the pressing screw is worn, it won't be able to generate enough pressure.

Regular maintenance is essential for the long - term performance of the oil press. You should lubricate the machine regularly, and replace the components according to the recommended cycle. Also, optimizing your usage habits can extend the life of the equipment. For example, don't overload the machine and clean it after each use.

Let's look at some real - world cases. In one family, they used the same type of sunflower seeds but with different pre - treatment methods. One batch was properly roasted at the right temperature, while the other was not. The properly roasted batch had an oil yield that was 20% higher. This shows that every step in the process matters.

It's important to emphasize that improving the oil yield is not just about the equipment. It requires the coordinated management of the whole process, from raw materials to equipment maintenance. By paying attention to every detail, you can significantly improve the oil yield, whether you're using it for family cooking or small - scale production.

If you're looking for a reliable household oil press, consider the Penguin Group's small - scale household sunflower oil extractor. It uses high - strength steel and a precise pressing structure to ensure long - term stable and high - yield production, which is suitable for family users who pursue high - efficiency oil extraction.

立即获取专属榨油效率诊断方案,售前专家一对一解答