Are you caught in the dilemma of selecting the right small-scale sunflower oil press machine for your needs? Whether you are a home user aiming for fresh, high-quality oil or a smallholder farmer striving to boost commercial production, understanding the core differences between home-use and commercial-use presses is crucial. This article delves into the technology trends, market demands, and real-world applications across Asia, Africa, and South America to help you make an informed investment.

From evaluating daily processing capacity and operational complexity to maintenance requirements and oil yield efficiency, we offer a scientific approach to your purchase decision—eliminating guesswork and enhancing your sunflower oil quality and production efficiency.

Home-use machines typically focus on simplicity and compactness, with daily processing capacities averaging between 10 to 20 kilograms. They prioritize ease-of-operation, low power consumption (under 1 kW), and minimal noise levels to suit household environments. Conversely, commercial presses target higher throughput, often processing 50 to 200 kilograms per day or more, equipped with robust components for continuous operation and advanced temperature control to maximize oil extraction efficiency and purity.

| Feature | Home-Use Press | Commercial Press |

|---|---|---|

| Daily Processing Capacity | 10–20 kg | 50–200+ kg |

| Power Consumption | <1 kW | 3–8 kW |

| Operation Complexity | Simple, manual or electric start | Automated controls, temperature regulation |

| Maintenance Frequency | Every 2–3 months | Monthly, professional servicing recommended |

| Oil Yield Efficiency | 40–45% | 50–60% |

In Southeast Asian rural households, compact electric presses have enabled families to produce their own sunflower oil daily, reducing dependency on commercial suppliers and ensuring organic product standards. These home-use units, operating under 1 kW electric power, have a typical runtime of 2 hours, producing approximately 15 kg of oil with minimal noise disruption.

Meanwhile, small farmers in East Africa have adopted semi-automated commercial presses integrated into modular processing lines. For example, a Kenyan cooperative recently upgraded to a 150 kg/day capacity system that improved oil yield by 12% and cut energy costs by 8%, positively impacting local economic resilience. The modular design allows customization for additional seed types such as sesame and groundnuts.

You might wonder, is it better to opt for a standalone oil press or invest in a full processing line? Standalone units offer portability and ease of use for home or small farm use but limit scalability. By contrast, complete lines – often deployed commercially – integrate cleaning, drying, pressing, and filtering functions, achieving higher output and consistent quality but demanding more space and technical knowledge.

Selecting the right equipment depends on multiple factors. Here’s what you should consider:

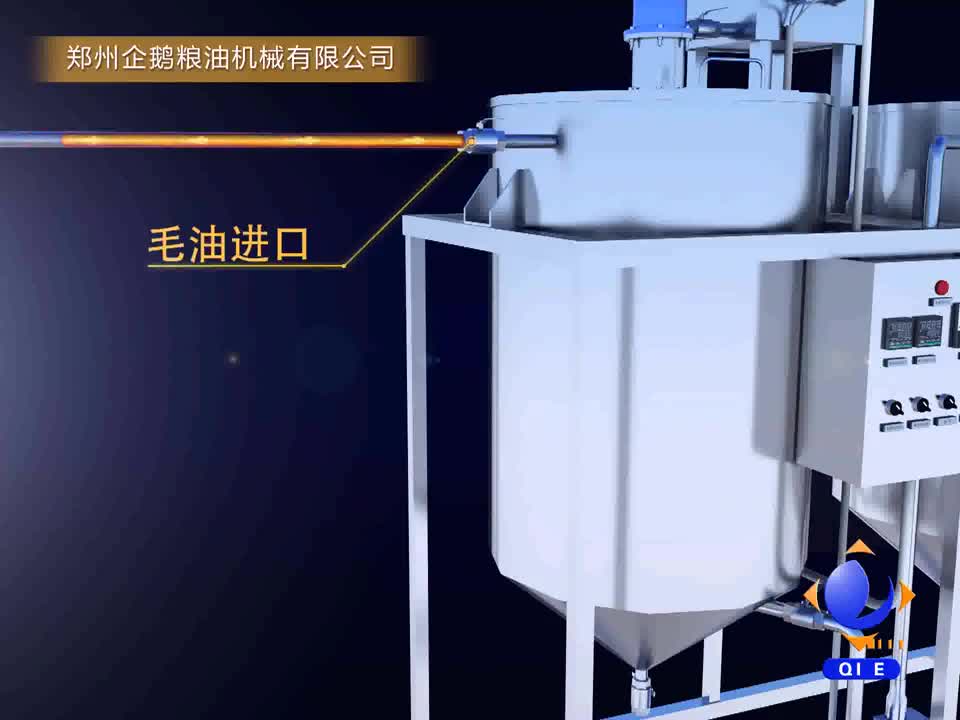

Penguin Group’s state-of-the-art presses combine compact design with high-efficiency extraction technologies, perfectly bridging the gap between home-use convenience and commercial robustness. Their proprietary screw press achieves oil yields up to 58% with low energy consumption. Installation is quick and simple, supported by a global network ensuring reliable after-sales support across Asia, Africa, and South America.

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)