In the global market, the demand for green and healthy sunflower oil is on the rise. Penguin Group's small sunflower oil presses have gained popularity among overseas buyers. This article aims to answer the common questions about the operation and maintenance of these presses, providing comprehensive guidance to help users achieve efficient and stable production.

Before starting the pressing process, proper seed pretreatment is crucial. First, clean the sunflower seeds to remove impurities such as dirt, stones, and broken seeds. This can improve the quality of the oil and protect the equipment. It is recommended to use a seed cleaner with a cleaning efficiency of over 95%. After cleaning, the seeds can be dried to an appropriate moisture content, usually around 8 - 10%. This can significantly increase the oil yield. For example, with a moisture content of 9%, the oil yield can be about 3 - 5% higher compared to seeds with higher moisture.

When starting the small sunflower oil press, follow the correct startup sequence. First, check the power supply and ensure that all electrical connections are secure. Then, turn on the main power switch and let the motor run idle for 1 - 2 minutes to check if there are any abnormal noises or vibrations. Next, adjust the pressing parameters according to the type and quality of the sunflower seeds. The temperature of the pressing chamber is usually set between 100 - 120°C, which can optimize the oil extraction process.

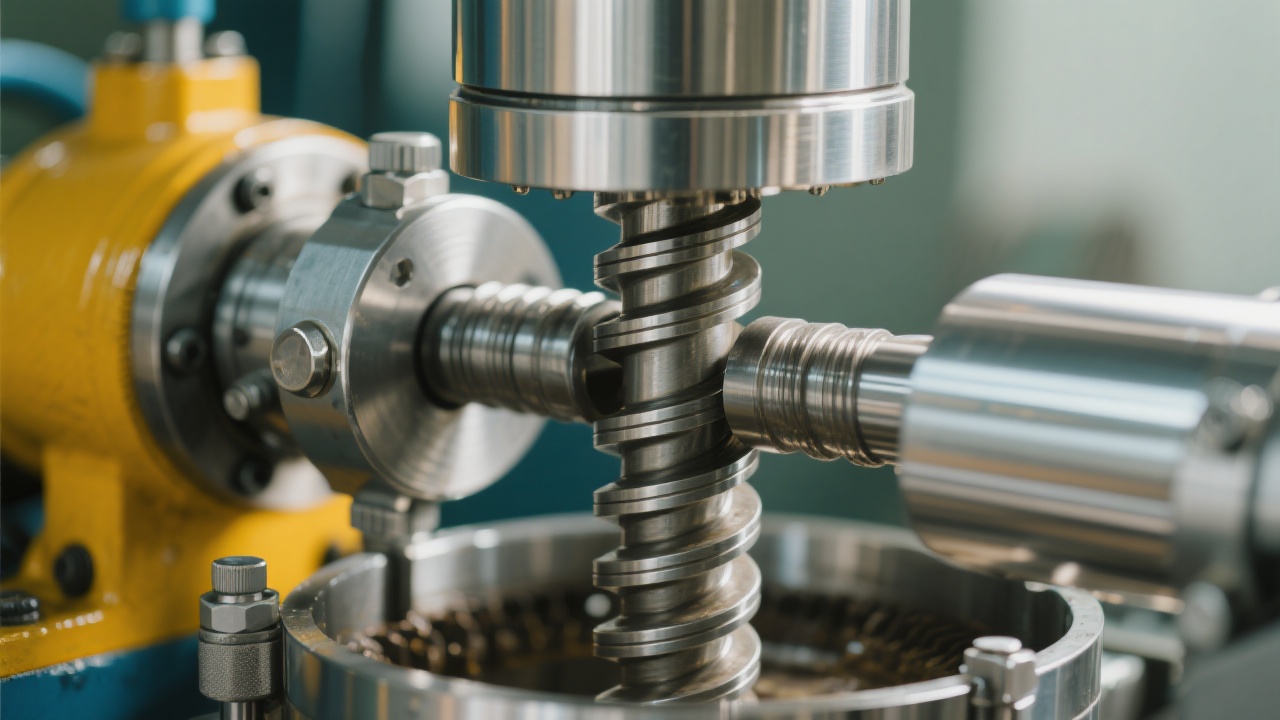

During the pressing process, the sunflower seeds are gradually fed into the pressing chamber. The screw in the chamber rotates to apply pressure, squeezing out the oil. The pressing speed should be controlled at a moderate level, usually around 20 - 30 kg per hour for small - scale presses. After pressing, the crude oil needs to be filtered to remove residues. A multi - stage filtration system can be used to achieve a high - quality oil product. The first - stage filtration can remove large particles, and the subsequent stages can further purify the oil. The filtration efficiency can reach over 98%, ensuring clear and pure sunflower oil.

Regular maintenance is essential for the long - term operation of the small sunflower oil press. Daily cleaning is necessary to remove residues from the pressing chamber, hopper, and other parts. This can prevent blockages and ensure smooth operation. Lubricate the mechanical parts regularly, such as the bearings and gears, using high - quality lubricants. Check the key components, such as the screw and the pressing chamber, for wear and tear every 1 - 2 months. If any parts are damaged, replace them in time to avoid affecting the performance of the equipment.

In case of equipment failure, first, check the power supply and electrical system. If there is no power or abnormal electrical signals, it may be a problem with the circuit or the motor. For mechanical failures, such as low oil yield or abnormal noises, check the pressing chamber and the screw for blockages or damage. If the oil yield is low, it may be due to improper seed pretreatment or incorrect pressing parameters. By adjusting these factors, the oil yield can be improved.

When operating the small sunflower oil press, always follow the safety regulations. Do not touch the moving parts during operation to avoid accidents. Wear appropriate protective equipment, such as gloves and goggles. Keep the work area clean and dry to prevent slipping. In case of any emergency, stop the equipment immediately and follow the emergency procedures.

Penguin Group provides global technical support for its small sunflower oil presses. Our professional technicians are available 24/7 to answer your questions and provide on - site service if necessary. We also offer regular software updates and technical training to help you make the most of your equipment.

If you are interested in our small sunflower oil presses and want to learn more about its operation and maintenance, or have any other questions, please click here to get in touch with us. We are committed to helping you achieve sustainable business goals with our high - quality products and excellent services.