Small sunflower oil presses have become increasingly popular among households and small farms due to the growing demand for fresh, high - quality sunflower oil. This guide aims to provide a comprehensive understanding of the differences between home - use and commercial small sunflower oil presses, offering practical advice on selection and maintenance.

The market for small sunflower oil presses is diverse, catering to different user needs. Home - use presses are mainly for families who want to produce a small amount of oil for daily consumption. They are designed to be used in a home kitchen environment. On the other hand, commercial presses are used in small farms or small - scale oil production workshops, aiming for higher output and continuous operation. For example, a family of four might use a home - use press to produce about 1 - 2 liters of sunflower oil per week, while a small farm could use a commercial press to produce 50 - 100 liters per day.

Home - use presses are usually more compact in structure and easier to operate. They are designed to be user - friendly, with simple buttons and clear instructions. Commercial presses, however, are more complex in structure. They often have a larger size and more components to ensure high - efficiency production. For instance, a home - use press may have a single - stage pressing mechanism, while a commercial press may use a multi - stage pressing system for better oil extraction.

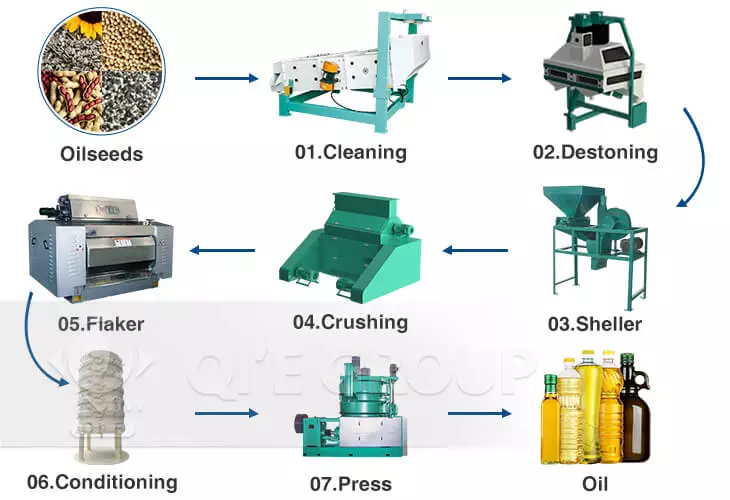

In terms of oil production efficiency, commercial presses have a significant advantage. They can process a larger amount of sunflower seeds in a shorter time. A home - use press may take several hours to produce a few liters of oil, while a commercial press can produce dozens of liters per hour. In terms of capacity, home - use presses are usually single - unit operations, while commercial presses can be part of a complete set of equipment, including seed cleaning, roasting, and oil filtering devices.

Home - use presses are suitable for a clean and dry home environment. They require less maintenance and can be easily cleaned with common household tools. Commercial presses, however, need to be used in a more professional production environment. They often need to meet ISO9001 standards for quality control. Regular maintenance is crucial for commercial presses to ensure long - term and stable operation. For example, the screw shaft of a commercial press may need to be lubricated and inspected every few days.

When choosing a small sunflower oil press, both home users and small - farm owners need to consider their processing scale and budget. For home users, a budget of around $200 - $500 can usually meet the demand. For small farms, the investment may range from $1000 - $5000, depending on the production capacity and equipment configuration. In addition, technical support is also an important factor. Some manufacturers offer after - sales training and maintenance services, which can save users a lot of trouble.

Take a small farm in the Midwest of the United States as an example. They initially used a home - use press, but as their production scale expanded, they found that the home - use press could no longer meet their needs. After switching to a commercial press, their daily oil production increased from 20 liters to 80 liters, and the oil quality also improved. They also learned how to maintain the press properly, which reduced the breakdown rate and saved costs.

Q: Can I use a home - use press for small - scale commercial production? A: It is not recommended. Home - use presses are not designed for long - term continuous operation and may not be able to meet the production capacity requirements. Q: How often should I clean a commercial press? A: It depends on the usage frequency. Generally, it should be cleaned after every 10 - 15 hours of operation.

If you are still unsure which small sunflower oil press is right for you, or if you have more questions about these products, feel free to contact us. Our professional team is ready to provide you with detailed information and guidance. Don't miss this opportunity to optimize your oil production process!

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)